What motivated this project is essentially how training is conducted for current distal radial fractures, which is a common wrist fracture. The problem lies in the displacement of information from a experienced surgeon to a junior as the training models differ from the actual surgery, thus resulting in a misaligned mental model. Such actually lengthens the training period. Furthermore, this affects the duration of the surgery as the conventional practice does not offer direct translation of 2 dimensional data (X-ray) into a 3 dimensional space (actual patient's wrist). This results in lesser patients being able to receive timely intervention.

This design offers 3 main solutions in respect to the highlighted problem.

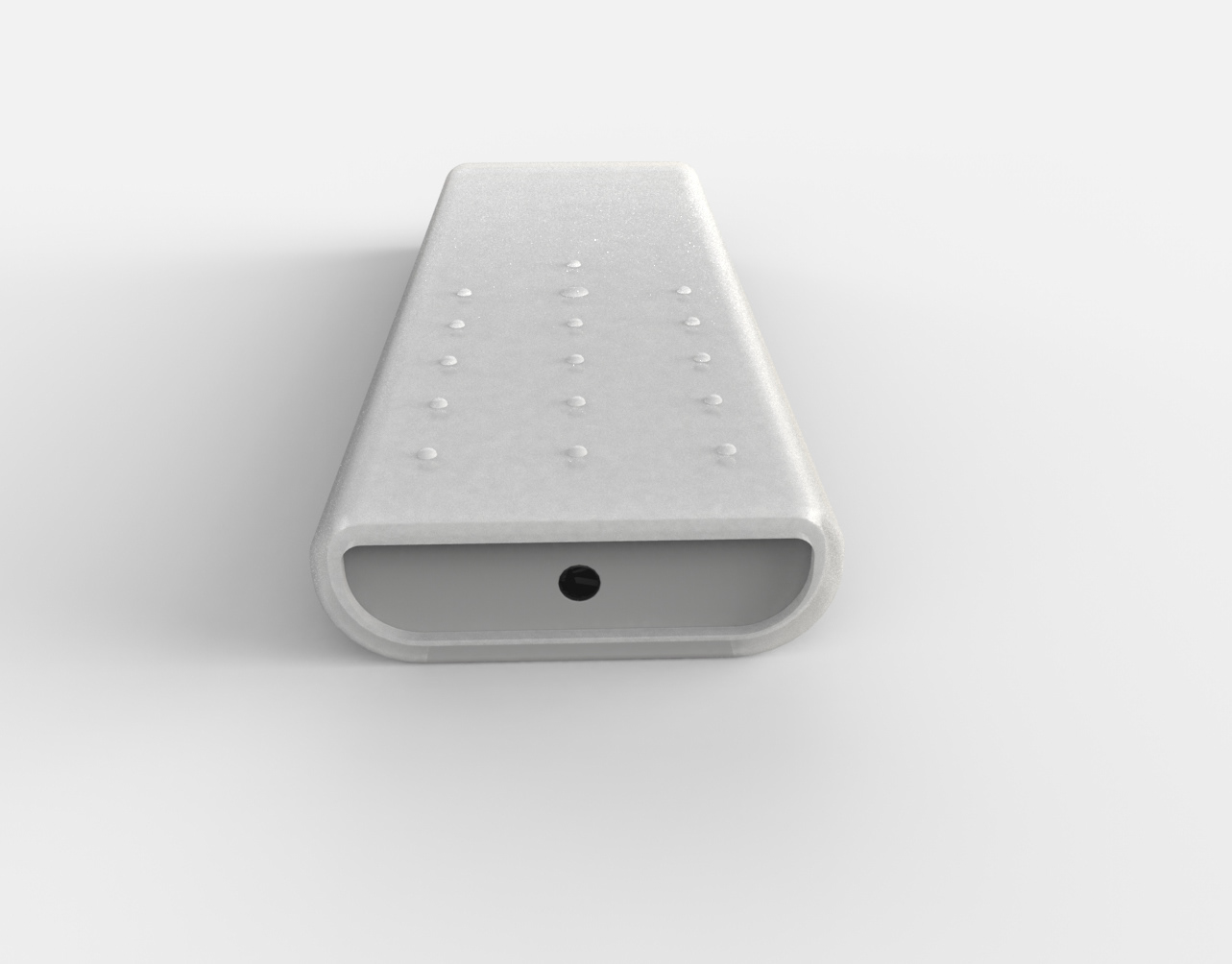

First, the main body of the model offers various operation windows which are consistent with that of the actual human wrist section. They are the styloid, palmar and dorsal approach windows. General contours of the human arm are abstracted such that the model will not remain static while junior surgeons are practicing, thus simulating realistic reactions.

Second, the internal package allows ease of disposal and analysis as it is a synthesized package. To increase the realism of the reaction, various grades of silicon such as Dragon skin 30 and RTV 585 were utilised. Moulds for the components are made with reference to anatomical structures based on the 50th percentile via CAD software. This allows mass production of the elements when required.

Last, the bone set (radius and ulnar bones) is made of a special remouldable thermoplastic which allows repetitive work to be done.

First, the main body of the model offers various operation windows which are consistent with that of the actual human wrist section. They are the styloid, palmar and dorsal approach windows. General contours of the human arm are abstracted such that the model will not remain static while junior surgeons are practicing, thus simulating realistic reactions.

Second, the internal package allows ease of disposal and analysis as it is a synthesized package. To increase the realism of the reaction, various grades of silicon such as Dragon skin 30 and RTV 585 were utilised. Moulds for the components are made with reference to anatomical structures based on the 50th percentile via CAD software. This allows mass production of the elements when required.

Last, the bone set (radius and ulnar bones) is made of a special remouldable thermoplastic which allows repetitive work to be done.